Why Engineers and Data Scientists are the Top Choices for CEO in Manufacturing

Table of Content

- Introduction: Manufacturing’s New Leadership Imperative

- From Efficiency to Intelligence: The Paradigm Shift

- The Engineer’s Edge: Why Technical Expertise Matters

- Three Cornerstones of Next-Gen Manufacturing CEOs

- Technology Imperatives for Tomorrow’s CEO

- Talent-Acquisition Implications for the Industrial Sector

- Building the Leadership Pipeline: A Search-Partner Playbook

- Conclusion

- FAQs

- Engineer CEOs in manufacturing are redefining its future by steering smart investments and embedding analytics into every executive decision.

- Leadership profiles are shifting from cost-centric oversight to strategic guidance of IIoT (Industrial Internet of Things) deployments, edge networks and predictive analytics platforms.

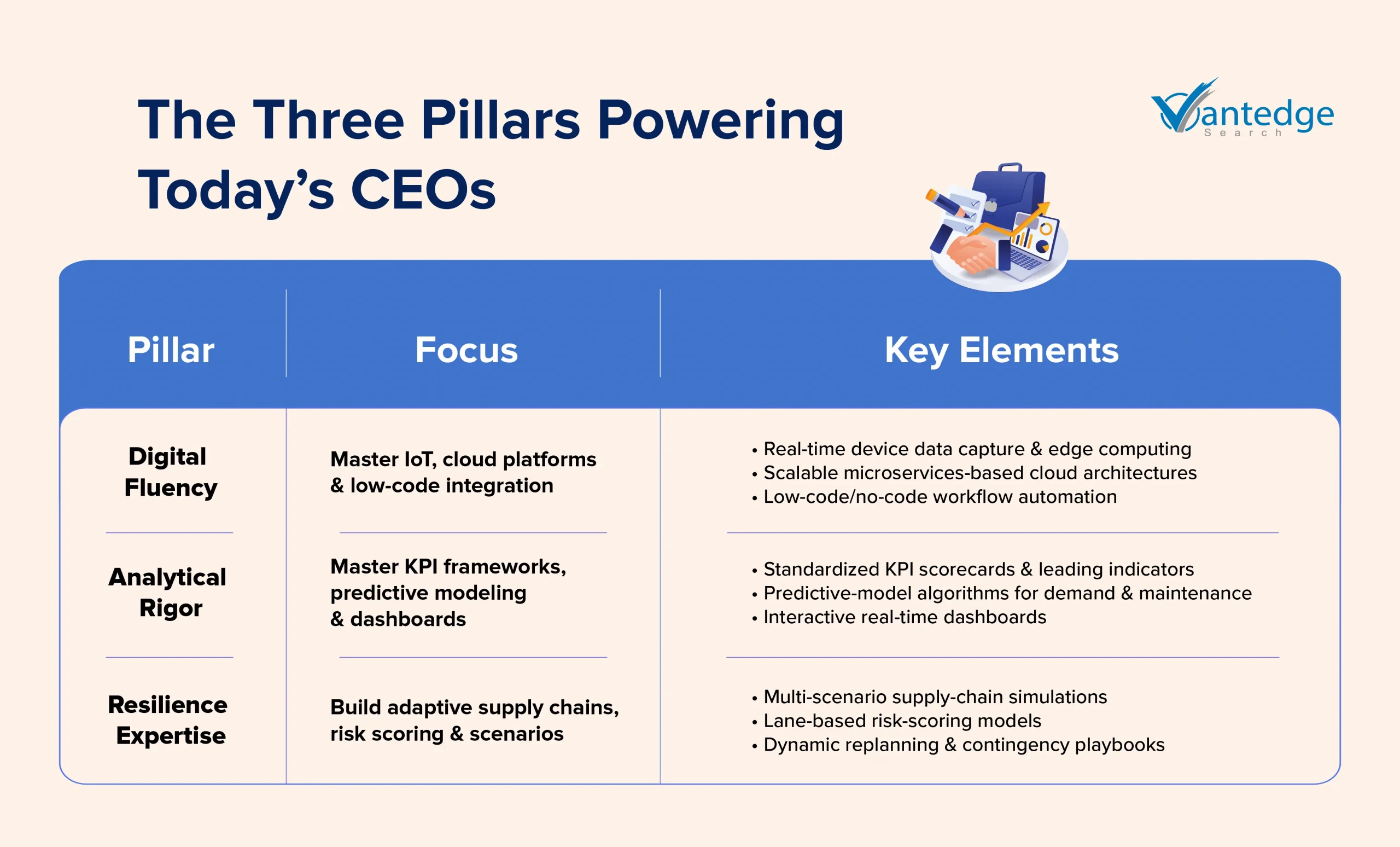

- Three pillars define modern CEO success: digital fluency, analytical rigor and resilience expertise anchor Industry 4.0 leadership and data-driven manufacturing.

- Talent acquisition must evolve with hybrid job descriptions, practical assessment centers and targeted outreach to secure engineer CEOs in manufacturing and data scientist CEOs in manufacturing.

- Onboarding and mentorship programs reinforce digital fluency for manufacturing leaders and align new executives with enterprise objectives from day one.

Manufacturing is going through one of the most dynamic periods ever, creating exciting new possibilities for leadership. By 2033, the industry will create around 3.8 million new opportunities for skilled professionals, highlighting tremendous growth potential. While some challenges exist with 1.9 million positions potentially hard to fill and 450,000 roles currently open as of March 2025, this talent landscape is driving innovation in how companies attract and develop their workforce.

At the same time, manufacturers are embracing the future with enthusiasm. 78% are investing more than 20% of their improvement budgets in cutting-edge smart manufacturing initiatives, and enterprise IoT spending soared to $269 billion in 2023 which is a 15% year-on-year increase.

Introduction: Manufacturing’s New Leadership Imperative

Manufacturing CEO trends highlight the need to balance process-driven leadership with data-driven decision-making, underscoring the role of data scientists in manufacturing leadership. Although IoT impact on manufacturing leadership and advanced analytics generate valuable operational intelligence, many companies struggle to translate that information into strategy without a CEO who connects technical specifications with corporate objectives.

As a result, boards are prioritizing engineer CEOs in manufacturing and data scientist CEOs in manufacturing. The need of the hour are leaders whose technical expertise and digital fluency for manufacturing can keep technology initiatives aligned with enterprise goals and bolster resilience in supply chain management. This means often working alongside a Chief Data Officer in manufacturing to advance digital transformation in manufacturing leadership.

Constraints of Efficiency-Centric Strategies

Lean programs and cost discipline once defined success on the factory floor. However, in an environment marked by raw material swings, logistics interruptions, and tighter capital, marginal gains from traditional efficiency measures can be quickly eroded. Companies allocating over 20 percent of their improvement budgets to smart-manufacturing efforts still struggle when leadership lacks the ability to convert real-time data into decisive action.

The Rising Demand for CEOs Who Blend Technical and Data Leadership

Organizations are increasingly promoting leaders who combine hands-on technical expertise with sophisticated data intelligence. When a CEO has an engineering foundation, they can confidently assess the real value of Industrial IoT platforms, edge computing solutions, and system integration approaches without relying solely on external advisors. Paired with strong data strategy skills, these leaders can transform dashboard insights and predictive analytics into smart decisions about where to invest capital and how to manage risk effectively.

This powerful combination of technical know-how and analytical thinking has become the gold standard for manufacturing leadership. Boards are actively seeking candidates who can skillfully harness both the physical operations, including the machines, processes, and systems, and the digital intelligence that drives strategic decision-making. It’s this ability to bridge the mechanical and analytical worlds that’s positioning these hybrid leaders to drive sustainable, long-term growth in an increasingly complex manufacturing landscape.

Secure Your Data-Driven

CEO today

From Efficiency to Intelligence: The Paradigm Shift

The role of manufacturing leadership is evolving from traditional cost-cutting focused leadership to something much more dynamic and strategic. As factories adopt smart machinery and integrated analytics, leadership must pivot from supervising production lines to directing information flows. This shift in digital transformation and manufacturing leadership places a premium on executives who can translate raw sensor outputs into actionable plans.

The move to data-driven manufacturing demands a deep understanding of how digital tools reshape processes. No longer is it sufficient to report on yesterday’s output; today’s leaders must anticipate disruptions and generate responses in near real time. This evolving expectation underscores why engineers are becoming CEOs in manufacturing.

How digital technologies and AI have remapped value chains

Connected devices now capture machine health, throughput rates and yield quality at every step. When paired with artificial intelligence, these inputs identify patterns that human supervisors might miss. A CEO versed in systems engineering can oversee IoT deployments, guide cloud-based analytics and calibrate algorithms to predict maintenance windows. In doing so, they ensure digital investments directly support operational agility and cost resilience.

The limits of traditional P&L-only leadership in volatile markets

CEOs who rose through finance ranks excel at budgeting and profit forecasting, yet they often lack the technical fluency required to evaluate analytics platforms or edge-computing architectures. In an environment defined by rapid component shortages and shifting customer demands, this gap can leave organizations reactive rather than anticipatory. Data strategist CEOs in manufacturing close that gap, aligning technology roadmaps with strategic objectives and securing durable competitive advantage.

The Engineer’s Edge: Why Technical Expertise Matters

In a sector where digital transformation in manufacturing leadership is no longer optional, CEOs must grasp the intricacies of equipment design, automation controls, and data architectures. Technical expertise in CEO roles enables executives to evaluate complex investments, whether in (Industrial Internet of Things) (IIoT) platforms, edge-computing gateways, or predictive analytics suites—and to guide multidisciplinary teams through large-scale modernizations.

Deep domain knowledge accelerates problem–solving

Leaders with engineering backgrounds can rapidly diagnose production bottlenecks, assess sensor integration challenges, and shape system-wide improvements. For example, GE’s Predix platform merges edge analytics with cloud-native microservices to optimize asset performance, allowing engineers-turned-CEOs to oversee predictive maintenance strategies with confidence.

Likewise, proficiency in connectivity protocols and real-time control loops lets a CEO weigh the trade-offs between on-premises PLC networks and scalable cloud deployments—ensuring that digital initiatives align with operational requirements and long-term resilience in supply-chain management.

Real-world examples: hardware, robotics, process automation

Many leading manufacturers highlight how technical fluency at the top yields tangible gains. Siemens deployed its MindSphere IoT solution on AWS to monitor production-line efficiency, advancing overall equipment effectiveness in under two months.

In robotics, integration of digital-twin applications has enabled automatic calibration of CNC tools and autonomous inspection routines, reducing unplanned downtime and manual intervention. These use cases underscore why data scientist CEOs in manufacturing and engineer CEOs in manufacturing must collaborate tightly combining hardware know-how with analytics insight to keep factories running predictably and profitably.

Three Cornerstones of Next-Gen Manufacturing CEOs

As manufacturing CEO trends continue to favor leaders who combine technical mastery with strategic insight, three cornerstones emerge as indispensable for today’s C-suite: digital fluency, analytical rigor, and resilience expertise. Together, these pillars define the skill set that engineer CEOs in manufacturing and data scientist CEOs in manufacturing must embody to steer their organizations through the complexities of Industry 4.0 leadership and data-driven manufacturing.

Digital Fluency

CEOs need a clear grasp on IoT’s impact on manufacturing and how to take advantage of technologies like sensors, edge gateways, and cloud platforms. Technical fluency lets them partner with a Chief Data Officer in manufacturing to set API standards, migrate legacy controls, and align technology investments with enterprise goals. This fluency accelerates digital transformation in manufacturing leadership, turning connected assets into reliable insights.

Analytical Rigor

Data-driven manufacturing depends on a disciplined framework for metrics. Data strategist CEOs in manufacturing establish consistent definitions for throughput and quality, validate predictive models and review dashboard outputs against strategic targets. Their hands-on involvement with data pipelines and analytic tools ensures every insight supports confident executive decisions.

Resilience Expertise

Building adaptive supply chains starts with risk-scoring and digital-twin simulations that anticipate disruptions. Engineer CEOs in manufacturing assess scenario outcomes and work with operations teams to embed contingency protocols into control towers. This resilience expertise underpins steady production and protects margins when unexpected events arise.

Technology Imperatives for Tomorrow’s CEO

As digital transformation in manufacturing leadership accelerates, executives must master key technologies that underpin Industry 4.0 leadership and data-driven manufacturing. Emerging imperatives include connected devices, virtual replicas, generative AI and security frameworks, all of which demand both technical expertise in CEO roles and the strategic instincts of data scientist CEOs in manufacturing.

IoT and Ubiquitous Connectivity: IoT impact on manufacturing leadership extends far beyond sensor installation. Today’s CEOs must assess network architectures, data ingestion pipelines and edge-to-cloud pathways to maintain uptime and reduce unplanned stoppages. An engineer CEO in manufacturing brings credibility when evaluating protocol standards, device management platforms and real-time analytics capabilities, ensuring that connected assets feed reliable insights into enterprise systems.

Digital Twins for Virtual Testing: Digital twins create mirror images of production assets and processes, allowing executives to test changes in a risk-free environment. Manufacturers that adopt this technology can model supply-chain shifts, evaluate equipment upgrades and tune throughput parameters before acting on the factory floor. Data strategist CEOs in manufacturing oversee the integration of these simulations with live data streams, making virtual testing a routine part of capital-planning reviews.

Generative AI to Accelerate Innovation: When combined with digital twins, generative AI can synthesize synthetic data sets, propose design alternatives, and speed up scenario validation. CEOs versed in both engineering principles and analytics can guide cross-functional teams in applying AI models to production scheduling, quality-inspection routines and demand forecasting ensuring that artificial intelligence contributes directly to margin improvement rather than remaining a pilot project.

Cybersecurity and Digital Risk Management: An expanded attack surface comes with every new connected device and cloud integration. Chief executives must champion cybersecurity strategies that cover both IT and operational technology domains, embedding secure-by-design practices into every project. Technical expertise in CEO roles allows these leaders to question security assumptions, set governance standards, and partner with CISOs to protect intellectual property and uphold customer trust.

Talent-Acquisition Implications for the Industrial Sector

Recruiting must keep pace with the shift in manufacturing CEO trends toward executives who combine engineering expertise with analytics insight. Today’s C-suite appointments must identify leaders capable of driving digital transformation in manufacturing leadership while upholding strict cost discipline.

Achieving this requires overhauling job descriptions, refining candidate evaluation techniques and expanding sourcing channels to attract engineer CEOs in manufacturing and data scientist CEOs in manufacturing who will champion data-driven manufacturing and preserve competitive strength.

Evolving Job Profiles: Hybrid JD requirements for Engineering + Analytics

Executive job descriptions must emphasize both hardware and software fluency. Rather than listing only mechanical or electrical engineering credentials, organizations should articulate expectations around predictive analytics oversight, dashboard interpretation, and partnership with IT stakeholders. Highlighting experience in IoT deployment alongside project-management rigor signals that technical expertise in CEO roles is non-negotiable. Clear articulation of these hybrid requirements helps boards understand why engineers are becoming CEOs in manufacturing and attracts candidates prepared for Industry 4.0 leadership challenges.

Assessing technical culture fit in executive searches

Beyond skills and titles, culture fit in the C-suite demands comfort with rapid data flows and continuous improvement cycles. Search partners should evaluate how candidates have collaborated with Chief Data Officer in manufacturing roles and led cross-functional teams through software rollouts. Structured interviews might probe a candidate’s method for translating sensor-generated insights into strategic plans, revealing whether they embody the data scientist CEOs in manufacturing profile. This focus on cultural alignment ensures that new CEOs will champion digital fluency for manufacturing leaders from day one.

Sourcing through university partnerships, internal upskilling, and niche communities

To build a pipeline of future engineer-data scientist CEOs, organizations can tap top technical universities and incubator programs where emerging leaders gain hands-on experience with advanced analytics and automation. Internal upskilling, like rotating senior engineers through data-science fellowships, reinforces retention and provides real-world exposure to data-driven decision making.

Additionally, engaging specialized forums for industrial IoT and predictive maintenance practitioners connects recruiters with professionals already versed in resilience in supply chain management and IoT impact on manufacturing leadership. These combined approaches deliver a steady flow of qualified candidates ready to meet the demands of modern manufacturing.

Building the Leadership Pipeline: A Search-Partner Playbook

Securing engineer CEOs in manufacturing and data scientist CEOs in manufacturing reflects key manufacturing CEO trends and supports broader digital transformation in manufacturing leadership goals. Search partners influence every phase, from candidate evaluation to integration by applying Industry 4.0 leadership principles and nurturing data-driven manufacturing mindsets.

Designing assessment centers that test code samples, data case studies and resilience exercises

Assessment centers can extend beyond traditional interviews by introducing hands-on exercises that mirror real executive challenges. Candidates might review a snippet of PLC code or interpret production data at scale. A resilience exercise could involve identifying potential supply interruptions and proposing responses grounded in system design. Observing how prospects blend engineering judgment with analytics insight offers clear evidence of their readiness for technical expertise in CEO roles.

Crafting EVP messages to attract “engineer-CEO” talent

An effective employer value proposition highlights opportunities to lead digital transformation in manufacturing, work alongside a Chief Data Officer in manufacturing and embed analytics into corporate strategy. Messaging that underscores respect for technical expertise in CEO roles and commitment to Industry 4.0 leadership resonates with candidates who seek to drive data-driven manufacturing at the highest level.

Onboarding and mentorship programs to sustain digital-first mindsets

Integration starts with structured onboarding that pairs incoming CEOs with veteran engineering and analytics leaders. Mentors from operations and data-science teams can guide initial decisions on IoT impact on manufacturing leadership and dashboard rollouts. Cross-functional rotations through IT, production and supply-chain functions reinforce digital fluency for manufacturing leaders. Regular executive forums ensure ongoing alignment with digital transformation objectives and help embed a data-driven manufacturing culture from day one.

Conclusion

Organizations at every level, from global boards and PE investors to HR & TA directors benefit when the CEO’s toolkit includes both engineering mastery and analytics insight. The shift toward engineer CEOs in manufacturing and data scientist CEOs in manufacturing reflects the imperative of digital transformation in manufacturing leadership and data-driven manufacturing. CEOs fluent in IIoT architectures, cloud platforms and predictive modeling can guide strategic investments with authority, while their credibility in the factory and boardroom accelerates adoption of new systems.

For HR teams, refining executive profiles to include technical expertise in CEO roles and digital fluency for manufacturing leaders becomes critical. For investors, assessing candidates on their track record with resilience in supply chain management and as a Chief Data Officer in manufacturing adds a new dimension to due diligence. As Industry 4.0 leadership demands both machine-level understanding and corporate vision, securing a CEO who excels in both domains is the most effective path to sustained operational resilience and strategic advantage.

Looking for a future-ready CEO to drive data-driven transformation for your manufacturing company? Partner with Vantedge Search today

FAQs

An Engineer CEO in Manufacturing Leadership brings hands-on technical experience to strategic decision making. By understanding machine design and data architectures, they align Industry 4.0 leadership initiatives with core business goals, ensuring investments in automation and analytics drive measurable ROI.

Current Manufacturing CEO trends favor candidates who combine deep engineering knowledge with analytics acumen. This dual skill set supports digital transformation in manufacturing leadership by guiding IIoT architectures and predictive modeling efforts with credibility in both the factory and boardroom.

A Chief Data Officer in manufacturing establishes data governance frameworks and ensures data quality across systems. Working alongside an Engineer CEO, they translate sensor data into strategic insights, reinforcing data-driven manufacturing and enabling more informed resource allocation.

Unlike legacy cost-focused models, Industry 4.0 leadership emphasizes connecting sensors, edge gateways and cloud platforms to surface real-time insights. CEO manufacturing roles now require fluency in automation controls and analytics to anticipate disruptions and guide continuous improvement.

By embedding digital transformation in manufacturing leadership practices—such as advanced analytics and connected assets—organizations bolster supply chain visibility and reduce unplanned downtime. This approach, led by Engineer CEOs and data scientist executives, fosters resilience and supports agile responses to market shifts.

Leave a Reply